Robotic Prosthetic Hand with Haptic Feedback

Arduino • Fusion 360 • FSR Sensors • Servo Motors

Designed 5-finger articulated prosthetic with force-sensitive haptic feedback enabling users to feel grip pressure through vibration motors.

Mechanical Engineering Student | Rice University

Building innovative solutions through hands-on design and prototyping

Mechanical engineering student passionate about robotics, automotive systems, and hands-on prototyping

I'm a Mechanical Engineering student at Rice University with a minor in Engineering Design, expected to graduate in May 2027. What excites me most about engineering is working on projects hands-on—prototyping and building physical solutions where I can see tangible results from my work.

I'm pursuing a career in robotics and automotive engineering, where I can combine my passion for hands-on design with cutting-edge technology. After graduation, I plan to either work in the automotive or automation industry, or eventually start my own company focused on innovative mechanical systems.

The process of building something from concept to reality and seeing the end result come to life always makes me incredibly happy and motivated. Whether it's designing a robotic prosthetic hand to help people feel with their fingertips, building antenna systems for rocket telemetry, or customizing electric bikes, I love the challenge of turning ideas into working prototypes.

SolidWorks, Fusion 360, OnShape, AutoCAD

3D Printing, CNC Machining, MIG Welding, Manual Machining

Python, MATLAB, Java, JavaScript, C++, Arduino

Arduino, Servo Systems, Sensor Integration, Circuit Design

A selection of mechanical engineering projects showcasing design, prototyping, and problem-solving

Arduino • Fusion 360 • FSR Sensors • Servo Motors

Designed 5-finger articulated prosthetic with force-sensitive haptic feedback enabling users to feel grip pressure through vibration motors.

SolidWorks • Mechanical Design • Field Testing

Engineered dual antenna mounting systems for Rice Eclipse rocketry team, tested at actual launch reaching 25,163 feet.

Carbon Fiber • 3D Printing • TPU Throttle • Electrical Systems

Built custom e-bike from individual components with carbon fiber weight reduction and 5-iteration TPU thumb throttle. Two years of daily use for campus commuting.

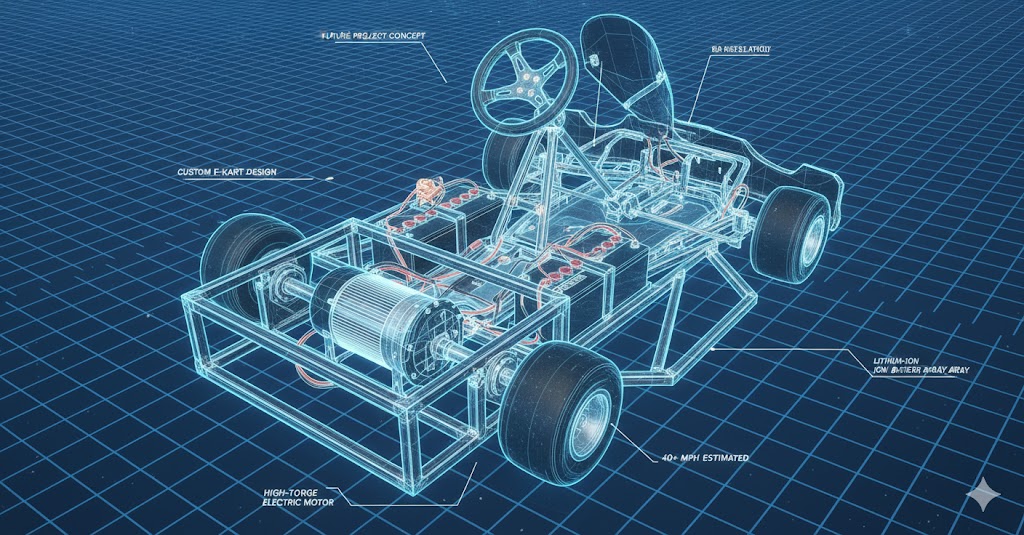

Chassis Design • Engine Integration • Safety Systems

Upcoming project: Design and fabricate a custom go-kart from scratch, applying mechanical engineering principles to create a high-performance recreational vehicle.

Interested in collaborating or learning more about my work?